TEXPORT is the global technological leader in the manufacturer of high-quality firefighting attire and protective work clothing.

In Salzburg Otmar Schneider founds a company for making protective clothing in a garage. At that time, no one could have predicted that he was laying the foundation for a unique success story. At that time no one was talking about protective clothing for fire fighters. Instead, they started out with the production of shoes and jackets for the Austria army.

The TEXPORT success story began with the manufacture of water-tight shoes.

Which leads to our scoring a major contract with the Austrian State of Styria. We deliver 10,000 suits. We also find new and more spacious administrative offices in Eugen-Müller-Street. And probably nobody thought that these offices would soon be too small.

Manufacture of functional attire with ISO 9001 Certification.

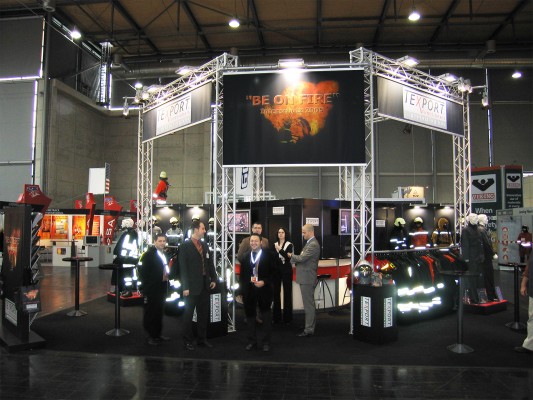

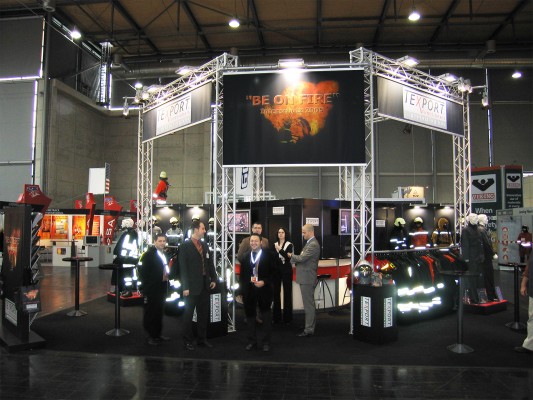

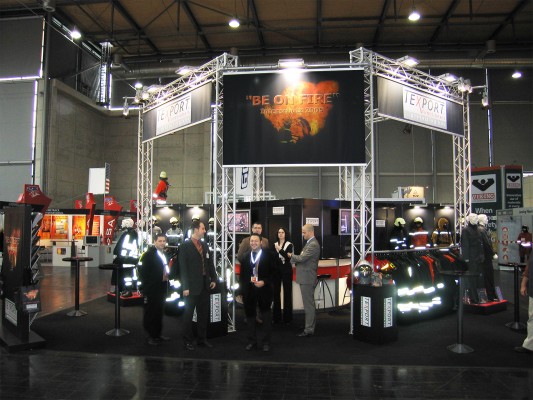

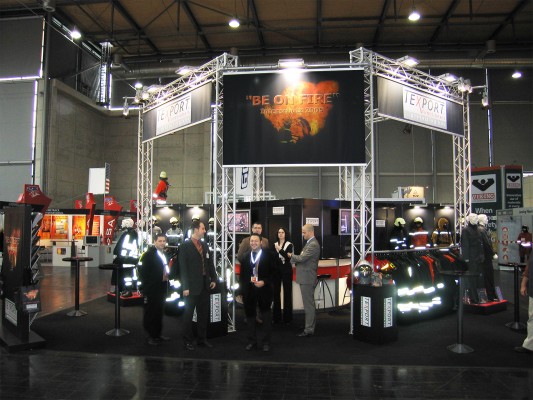

TEXPORT participated in the most important trade show in the emergency services support industry for the first time. New products and product lines were developed specifically for this event. The attendees were especially interested and impressed with the brand-new ULTRALIGHT® series, the HUPF AIRLOCK® line of attire and the sensitive first responder gloves FIRE-FOX®. Size of our booth at the show: 70 m2, employees on site: 7

TEXPORT moved its main office to Franz-Sauer-Straße 30 in Salzburg, Austria. The company’s larger building offered modern rooms and an expanded infrastructure which gave the company the best position for future growth and innovation.

A new major contract demonstrates the increasing international trust in TEXPORT. The German Federal Ministry orders 50,000 specialised overalls for the area of ABC-protection.

Encouraged by the success of Interschutz 2000, we were able to present the industry public with new milestones in high-grade protective clothing just five years later. This included the FIRE-TWIN®, the TEXPORT LADIES-series, the TEXPORT FIRE BREAKER firefighting suit as well as service attire made out of 100% NOMEX®. TEXPORT was already quite aware of the importance of proper care and cleaning of firefighting suits and protective attire. Our slogan this year was „How do I care for firefighting suits properly?“, and we brought the importance of this task home to the public to great effect. Size of our booth 80 m2, employees on-site Ort: 8

Start of a series of events called TEXPORT Action Days in Austria and Germany.

TEXPORT sets new standards with two patents of its own: X-TREME® and TEXPORT Triple Fabric®. This move further cements its reputation as a leader in innovation at the vanguard of the functional attire industry.

This year the trade show sees us present the world premieres of the two newly developed material structures X-TREME® and X-TREME light® . With this step, TEXPORT redefined the limits of the possible in the intersection of protective performance and wear comfort yet again. Fire departments such as those in Saudi Arabia switched their equipment to the new TEXPORT-products soon afterward. Size of our booth: 105 m2, employees on-site: 10

As one of the largest calls for tenders for the firefighting attire industry in all Europe, this call for tenders from the Berlin fire department encompassed a total volume of 5,515 suits. The call put an emphasis on both meticulous craftsmanship a well as extremely good protection and wear comfort.

The unique reputation of the TEXPORT brand has now spread far beyond the borders of Europe. This enabled us to secure high-value high-volume contracts with the calls for tenders for fire departments in Rio de Janeiro and Brasilia. In Europe, we welcomed the fire departments from Madrid and Rotterdam as new customers.

In 2012, the new production facility in Bulgaria (Kavarna) was opened to great celebration. The property extends over 4,400m2, on which a modern production facility with an area of 2,470m2. This expansion makes it possible to increase production capacities considerably as well as to react more efficiently to growing demand.

TEXPORT carried out an important re-launch of its logo which thoroughly modernised the visual presentation of the company. The new logo was an expression of a fresh, dynamic approach which underscores our continuing refining of our products and the company’s expansion on international markets.

The re-launch was not just a visual adjustment but also reflected TEXPORT’s claim to continue offering the highest quality, trailblazing technologies in a constantly changing market environment.

TEXPORT carries out the construction of its new facility in Vinica, North Macedonia. The facility extends over a developed surface of 1,600 m2 and a ground area of 6,500 m2. It is fully airconditioned and has a solar power plant. There is a cantina, offices, meeting rooms, two warehouses, and huge sewing hall for the approximately 300 employees.

This trade show appearance needed two years of painstaking planning. But TEXPORT once more succeeded in setting new standards for brand presentation. We operated our own sales stand for the first time which met with terrific enthusiasm from the visitors. The TEXPORT FIRE EXPLORER product group was recognised on-site with DUPONT™ NOMEX® GARMENT INNOVATION AWARD and so underscored the trailblazing role of the company from Salzburg. Size of our booth: 300 m2, employees on-site: 25

The product is the star. With the “Invisible Man”, TEXPORT raises its product-marketing to a new level. The lavishly produced picture and video materials for our TEXPORT product families present the product optimally.

The new production facility in Ilinden, North Macedonia, was opened after only 12 months of construction and provides space for 400 employees. The workplaces are ergonomically designed, and the entire plant is fully airconditioned, in order to assure optimal working conditions. The expansion was a logical consequence of the desired to continue to serve our core markets in Austria and Germany with our unchanged high TEXPORT-quality.

In 2019 the TEXPORT Headquarters in Salzburg in Franz-Sauer-Straße 30 is polished to a new shine. Along with the extensive measures for modernisation, it was possible to integrate parts of the building used for other purposes into the headquarter of TEXPORT.

The ever-increasing demand for TEXPORT products as well as the growing production capacities lead to an expansion of the warehouses at the Salzburg location. So, an expansion of 1,300 m2 provided the necessary capacities for handling grey goods.

TEXPORT won a significant call for tenders from the German Army and will take on the supplying personal protective gear (PPG). In this, specially developed details were integrated in order to fully meet the demanding requirements. The highly functional surface material IB-Tex as well as the innovative X-Treme construction in the jacket and the X-Treme light® structure in the trousers deserve special emphasize. The German Army is an especially valuable customer which TEXPORT will also present new, positive challenges in the coming years.

Mr. Schneider takes the first step in the direction of his well-deserved retirement. He continues to be involved in a consulting position for strategic decisions, takes care of selected key accounts and provides support for certification and development. His daughter Nicole Heinemann is assuming the function of operational management.

During our appearance at the Interschutz 2022 trade show, both the size of our largest presentation in the history of TEXPORT and the collection we presented met enormous interest among visitors and customers. The highlight was the presentation to the world premiere of the new series FIRE X-FLASH, FIRE RECON THL and FIRE RECON WILDLAND.

After 30 years, TEXPORT has grown from a tiny company operating out of a garage into a company that it active world-wide. The vision of Otmar Schneider and his family is embodied in the brand TEXPORT, and the family thus wrote its very own “TEXPORT Story”.

The production facilities were comprehensively modernized, and the machines were brought up to newest state of the art, in order to optimize work processes. These improvements serve to simplify work for employees and increase efficiency.

TEXPORT is now ISO-certificates in the areas of development, production and trade in functional attire as well as distribution of functional attire. The certificates confirm the compliance with high quality standards and efficient processes in these areas.

TEXPORT was entrusted with a highly exclusive contract from the fire department of Singapore, which is especially important to the company. In the framework of the highly prestigious project, TEXPORT will deliver 12,000 suits of the specially developed model “Fire Survivor X” over a period of three years. Made from the first-class surface material PBI, the model meets the strict requirements of the Singapore Fire Department and is available in different configurations. To date, 3,400 suits have been delivered. This extraordinary order makes their trust in the competence and quality of TEXPORT clear.

TEXPORT takes a clear step to increase sustainability and has purchased 16 new hybrid vehicles for field sales and service. This reduces our CO₂-footprint and strengthens our dedication to environmentally friendly transportation. The new vehicles combine modern technology and efficiency, so that we will continue to do our work effectively and with an eye on protecting the environment.

I accept the use of cookies which are essential for the function of the website (essential cookies), to offer me products and services which match my areas of interest and which make it possible to generate statistics (performance cookies) as well as those enabling me to access customised products and services on the website (marketing cookies). I can revoke my consent at any time. If you do not want to consent to these, we will limit ourselves to using the essential cookies and the contents will not be customised for your use. You can find additional information here. You can change your settings at any time by calling up the Cookie Settings at the top of the page