Regular and appropriate care of TEXPORT clothing will ensure optimal functionality and safety, guaranteeing a long service life for the material. Please comply therefore with the care instructions attached to the clothing in question.

General care instructions for TEXPORT products can be found in the supplied user information and downloaded here.

Also find several different and detailed recommendations from our material manufacturers concerning the care and laundry of the clothings.

GORE®, GORE-TEX®, WINDSTOPPER® and AIRLOCK® are brands of the W.L. Gore & Associates DuPontTM®, Nomex® and Kevlar® and are registered trademarks or trademarks from E.I. du Pont de Nemours and Company or by its partners. PBI® and PBI® Matrix are registered brands from PBI Performance Products, Inc.

The correct cleaning and care of your protective clothing is very important. Correct treatment guarantees optimal protection and prolongs the service life of the clothing. It is therefore essential to comply with the care instructions.

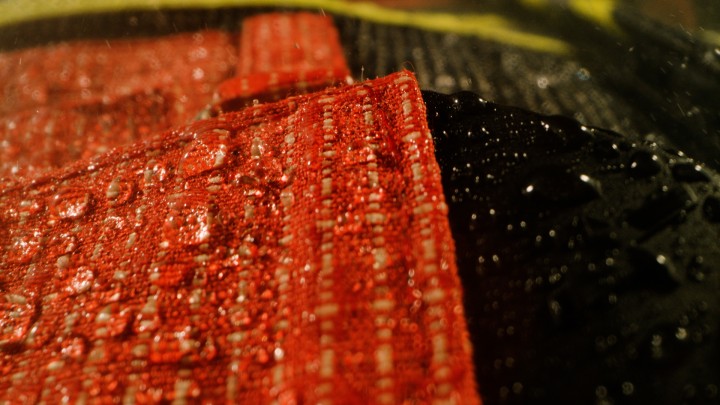

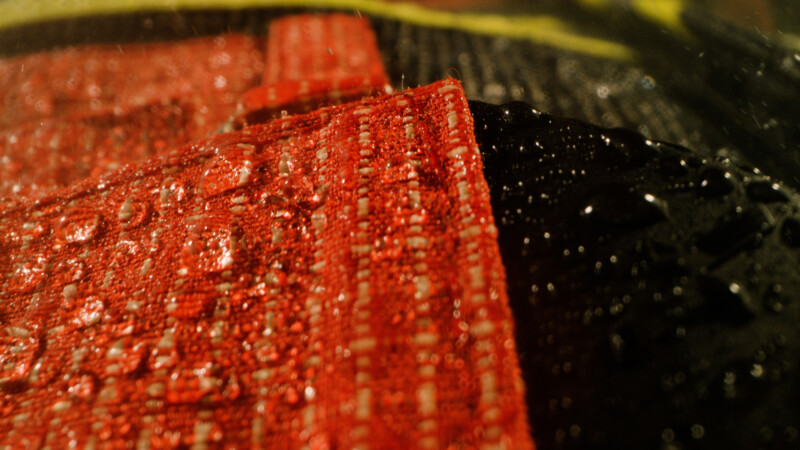

Protective clothing at TEXPORT is usually impregnated with fluorocarbon (FC). The surface material impregnation has no effect on the water tightness of the clothing.

This results solely from the membrane. If the surface material is not treated, the fabric can absorb more water which leads to the clothing gaining in weight.

Hint: We recommend impregnation exclusively with FC resins.

The original water and oil-repelling impregnation of the surface material will decrease in effect after several washes or longer periods of wear. Rain and other liquids can be drawn into the interior and the insulating lining via the seams.

Wear comfort drops rapidly with wet inner linings, the clothing increases in weight and there is even a risk of scalding when used in the firefighting sector.

This is why TEXPORT uses specially developed suction seals in the front, arm and seam areas. These permanently prevent the penetration of liquids via the hem seams. TEXPORT uses suction seals in both the firefighting (with flame-retardant materials) and workwear sectors.

Example: Front closure: The jacket closure is covered by two panels (double cover trim) and functions like a rain gutter. The lateral penetration of water is thus prevented.

In general, there are no legal replacement rules for firefighting clothing as is the case for e.g. helmets or straps. Service life is greatly dependent on the actual level of use. In most cases, clothing in the sector of voluntary fire brigades has a longer service life than that of professional fire brigades as the professionals tend to use their clothing more frequently.

Rule of thumb (without guarantee): An average service life of ca. 10 years. This is calculated based on the various levels of use and stresses recorded by fire brigades and institutions.

Hint: Once 10 years have elapsed, consideration should be given to using the latest technologies!

Standards

- EN 13688 Protective clothing -General requirements

- EN 343 Protective clothing – Protection against rain

- EN 469 Protective clothing for the fire department -Performance requirements for protective clothing for fire-fighting

- EN 20471 High-visibility reflective clothing

- EN 659 Fire-fighting safety gloves

- EN 1149-1 Protective clothing – electrostatic properties – Part 1: Testing procedures for the measuring of surface resistance

- EN 1149-3 Protective clothing – electrostatic properties – Part 3: Testing procedures for the measurement of charge decay

- EN 1149-5 Protective clothing – electrostatic properties – Part 5: Performance requirements for materials and constuction requirements

- EN 11612 Protective clothing – Clothing for protection against heat and flames

- EN 13034 Protective clothing against liquid chemicals – performance requirements on chemical protective clothing with limited protective performance against liquid chemicals (Equipment Type 6 and Type PB [6])

- EN 13911 Protective clothing for firefighters -requirements and testing procedures for fire protection hoods for the fire brigade

- EN ISO 14116 Protective clothing- Protection against heat and flames – materials, material combinations and clothing with limited flame propagation

- EN 1498 Personal fall safety gear, rescue loops

- EN 358 Protective gear for workplace positioning and fall prevention

- EN 361 Protective gear against falls-safety harness

- EN 813 Personal fall safety gear -sit harness

- EN ISO 15384 Protective gear for the fire brigade – lab testing procedures and performance requirements for protective clothing for firefighting in open areas

- EN 16689 Protective clothing for fire brigades -performance requirements for protective clothing for technical rescues

- EN 50286 Electrical insulating protective clothing for work in low-voltage systems

- EN 61482-1/2 Live-line work -Protective clothing against the thermal hazards of an electrical arc – Teil 1-2: Testing procedures – Procedures 2: Identifying the electric arc protection class of a material and clothing using a directed electric test arc (Box-Test) (IEC 61482-1-2:2007)

Safety vest exemption

Many European countries have not yet issued any statements on this topic. In Germany specifically, this topic is uniformly regulated for the whole of the Federal Republic by the DGUV paper (German Social Accident Insurance).

This paper refers to Appendix B, EN 469:2005, which regulates the minimum quantity and positioning of reflective stripes. This DGUV paper specifies that persons are exempted from wearing warning vests in secured accident areas.

Other countries are already taking this topic into consideration, further developments are to be expected.